Innovative laser surface cleaning

With our technology, we effectively clean and restore metal, natural stone, wood, glass and plastics.

Let the light work for you.

Do you have questions about your needs? Get in touch, we will answer your questions quickly and in detail.

Removal of old paint, varnish and cladding

Laser cleaning allows layers of unwanted coating to be removed very easily and quickly from a variety of materials.

Removal of graffiti and dirt from walls

The laser beam removes unwanted graffiti from walls as well as tarnish and dirt that has built up over time. Our technology

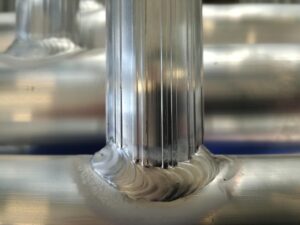

Pre-weld preparation and post-weld cleaning of welds

Thanks to the pulsed laser beam, it is possible to prepare the required surface before the metal joining process and clean the

Cleaning of boats and yachts

We clean various types of dirt, adhesives, abrasions, corrosion and organic deposits. We also prepare the surface for painting and protective coatings.

Removal of soot and charred areas from fires

The use of our technology makes it possible to restore the properties and appearance of places and objects after a fire. Surfaces

Restoration of cultural and historical sites

The laser we use allows us to safely restore cultural and historical sites such as monuments, gravestones, sculptures, pavements, furniture, etc. We

Grease and oil removal

The pulsed laser action cleans metal parts from oil and grease residues. This solution is safe for the parts being cleaned, such

Renovation and surface preparation of wood

Our state-of-the-art technology removes layers of paint, varnish and organic tarnish from the wood, while remaining safe for the base material.

Removal of organic residues

We safely remove organic soiling from process equipment generated during the production process. We work with the food industry, waste treatment and

Maintenance of machinery and tools

The laser beam is very helpful in removing dirt, grease, corrosion, paint, plastics and other unwanted residues in the working environment of machines.

Removal of rust and oxidation layer from metals

Using the laser, we remove the resulting tarnish on ferrous and non-ferrous metals while maintaining their original physical and chemical properties.

Advantages of the pulsed laser

Laser cleaning technology offers a host of advantages over conventional surface treatment methods such as grinding, sandblasting, water pressure washing and the use of chemicals. It is distinguished by:

- no use of chemicals

- no nuisance waste and dust

- quiet operation

- full protection of the base surface (non-abrasive and selective cleaning)

- immediate effect

- can be operated anywhere (even without permanent electricity supply)

- non-contact surface treatment

- complete safety for people and the environment

Who we work for

Thanks to the variety of applications for the pulsed laser and our experience, we work with a wide range of industries. We meet requirements and ourselves suggest places where the application of our technology will make the customer’s business work even better. Click the button below and check out our portfolio for yourself.